Peninsular Acoustics was engaged to provide acoustic consultancy, sound insulation testing and air pressure testing for a new residential development project consisting of eight flats across three floors.

The aim of the acoustic consultancy was to ensure that the separating floor and wall structures met the performance standards outlined in Building Regulations Part E, with particular emphasis on achieving acceptable levels of sound insulation between dwellings and therefore meeting industry standards for noise control.

ANC accredited Sound Insulation Testing (Pre-completion testing) was undertaken on completion of the project, which successfully passed all acoustic performance standards.

Air Pressure Testing was undertaken on completion of the project, which successfully passed all tests achieving the required design air permeability required by the SAP Calculations.

Acoustic Consultancy

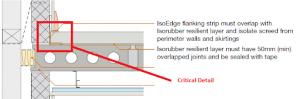

The acoustic consultancy highlighted critical installation details for the separating floor structure which consisted of a floating screed on resilient layer on a concrete plank, with dropped metal frame ceiling detail below. One example of a critical area was with the installation of the floating screed over an acoustic resilient layer.

This proposed floor system would typically provide impact sound insulation tests results with good performance comfortably meeting the requirements of Building Regulations Document E 2003, however, this is critically dependent on installation of the floating screed. Poor installation by bridging the screed across the resilient layer, leads to the most common new build sound test failure situation.

Assuming good installation a test result average of mid 50’s Lntw can be expected which is better than the requirement of equal to or below 62dB Lntw.

Why is the floating screed installation critical?

If the screed makes contact with the concrete structure below or the external block walls, a bridge in the resilient layer has occurred and the screed is no longer independent from the floor and wall structure of the building. If this happens the test performance will reduce dramatically.

Key Considerations on installation –

-

-

- Ensure the Regupol is correctly taped at joints between the rolls.

- Ensure the perimeter isolation is correct.

-

-

-

- Sub-contractors are often used onsite to install the floating screed. Check they have received the correct training, and are using the correct materials, not just the cheapest materials at the time they found to do the job. It is also critical to prepare the floor for the screed contractor prior to their site attendance.

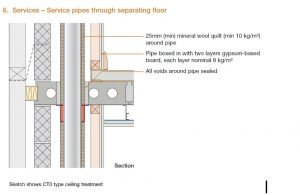

- Isolation of service penetrations through the separating floor is critical to avoid bridging the resilient layer. Please see below.

-

The floating screed products used DB FFR 6mm underlay with associated perimeter strip supplied by the sound insulation store, rather than the Regupol detail initially discussed.

Some onsite Photographs of the floating screed installation were taken. Correct Isolation of the waste pipe from the floating screed, and good perimeter floor isolation.

An underfloor heating system was installed within the floating screed.

Results and Compliance

1. Our acoustic design involvement helped to achieve optimal sound insulation between dwellings, ensuring a comfortable living environment for residents and compliance with Building Regulations Approved Document E.

2. The Association of Noise Consultants (ANC) accredited pre-completion testing confirmed that the structures met or exceeded the required acoustic performance standards, providing assurance to building control authorities.

After the ANC Accredited Testing a certificate and report were provided on completion.

There were a number of companies involved in the project:

Acoustic Consultant – Peninsular Acoustics

Architect – Seddon Associates

Developer – Direct Developments Limited

Floating Floor Supplier – Sound Insulation Store